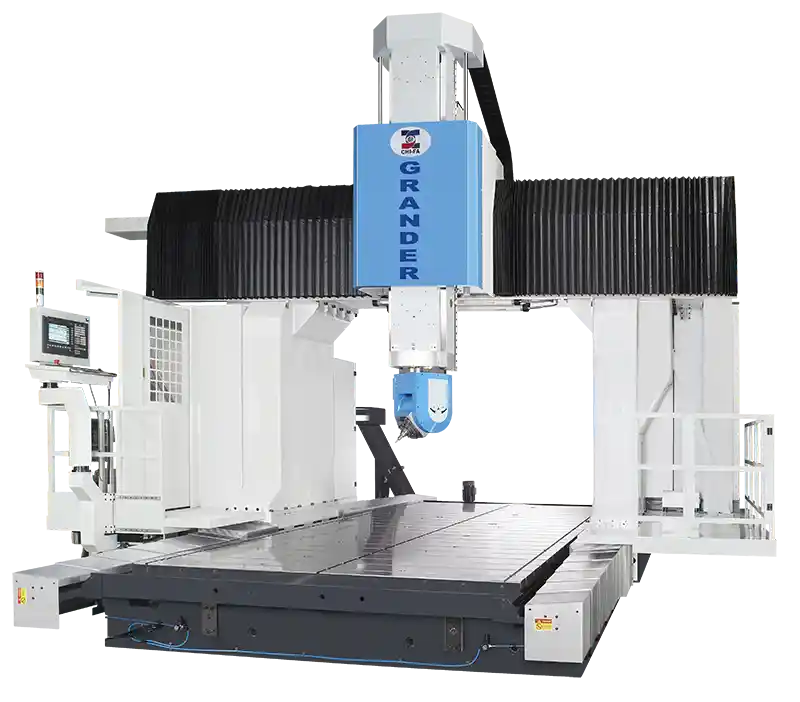

GRANDER Series Moving-Column Type 5-Axis Machining Center

● Single workpiece clamping setting can be used for multi-face milling or continuous 5-axis milling.

As a trusted 5 axis machining factory, we specialize in designing and manufacturing high-precision solutions for various machining needs. Our commitment to quality and innovation is reflected in every aspect of our machines, from the ergonomic design to the advanced technology incorporated.

● The Italian original factory participates in the entire design and manufacturing process of this model, and its mechanical structure and design technology are stable and mature.

● This model has been marketed in Europe for more than ten years and has been recognized and appreciated by the majority of users.

● The machine adopts modular design and can be equipped with various five-face heads or five-axis heads. It is suitable for complex body processing needs such as aerospace, rail, automobile and locomotive sheet metal molds, aerospace parts, green energy industry, LCD panel molds, and shipbuilding industry.

● Built-in high-torque and powerful spindle provides a wide range of applications, including rough milling, semi-finish milling and fine milling.

● Equipped with high-speed/low-torque or low-speed/high-torque spindle head to accommodate different material processing.

● Single workpiece clamping setting can be used for multi-face milling or continuous 5-axis milling.

● All moving axes adopt a fully closed-loop optical scale feedback system.

● There is no need to configure an automatic switching device, saving maintenance and reducing the failure rate.

● It can be configured into dual work areas, one of which can work and the other can load and unload workpieces, saving time and improving efficiency.

| Model | Unit | GRANDER 5A |

| Stroke | ||

| X Axis | mm | 4,000 or above (+1,000) ~ 40,000 |

| Y Axis | mm | 2,500 / 3,000 / 3,500 |

| Z Axis | mm | 1,000 (Opt.: 1,250) |

| Distance Between Columns (DBC) | mm | 2,500 / 3,000 / 3,500 |

| Head (TTFE3) | ||

| A Axis (Tilting) | degree | +95 ~ -120 |

| C Axis (Rotating) | degree | +/-200 |

| Work Table | ||

| Table Size (X Axis direction) | mm | 4,000 or above (+1,000) ~ 40,000 |

| Table Size (Y Axis direction) | mm | 2,000 / 2,500 / 3,000 |

| T-slot Configuration (Width/Pitch) | mm | 22 / 240 |

| Max. Loading | kg/m2 | 2500 |

| Spindle | ||

| Spindle Nose To Table Surface | mm | 200~1,200 (Opt.: 200~1,450) |

| Spindle Driven Method | Built-in | |

| Spindle Taper | HSK-A63 | |

| Spindle Motor Power | kW | 35 / 49 (S1-Cont. / S6-40%) |

| Spindle Motor Torque | Nm | 120 / 170 (S1-Cont. / S6-40%) |

| Spindle Speed | rpm | 12,000 (Opt.: 15,000) |

| Rapid Feedrate | ||

| X,Y Axes Rapid Feed | m/min | 20 |

| Z Axis Rapid Feed | m/min | 20 |

| Cutting Feed | m/min | 10 |

| ATC | ||

| ATC Type | Chain type | |

| Tool Number | T | 32 (Opt.: 40 / 60) |

| Max. Tool Weight | kg | 8 |

| Max. Tool Diameter (With Adj. Tool/Without Adj. Tool) | mm | Φ75 / Φ120 |

| Max. Tool Length | mm | 300 |

| Accuracy (ISO 230-2) | ||

| X/Y/Z Axis Positioning | mm | 0.03 or above (+0.005 per meter) |

| X/Y/Z Axis Repeatability | mm | 0.02 or above (+0.005 per meter) |

| General | ||

| Required Air Pressure | kg/cm2 | 6 |

| Machine Weight | kg | Please contact us for more info. |

| Machine Dimension (WxDxH) | mm | Please contact us for more info. |

| Standard Accessories | Optional Accessories | Controller Options |

|---|---|---|

|

|

|

Download

Download